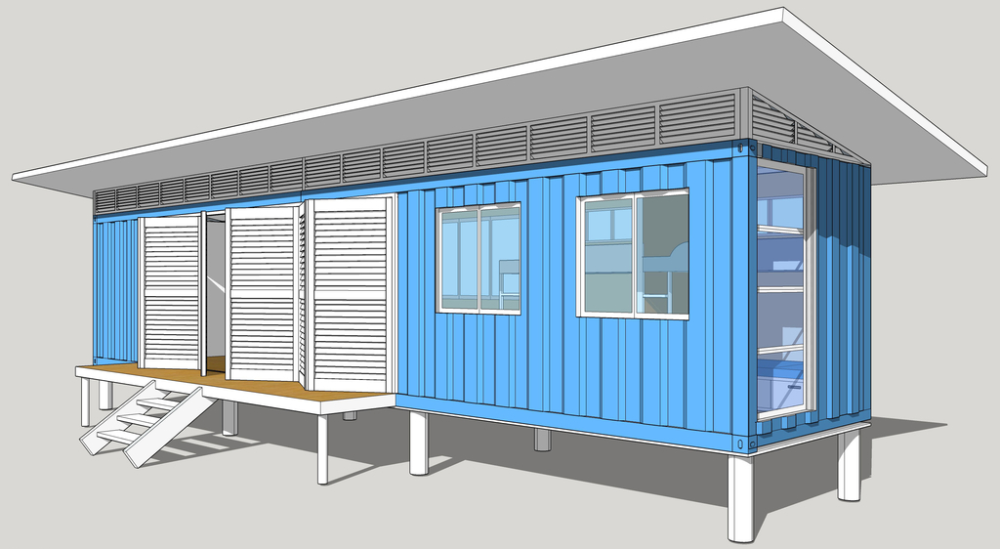

Containers were originally designed to carry heavy loads and to be stacked. They can also withstand harsh environments. So sturdiness and durability are must performances! If you need both durability and sturdiness, and need a cheap and beautiful livable house then you can check out container houses.

2. Low cost

The manufacturing process and material resources of container houses are less, which can save the construction of larger and more expensive foundations. Even buying a brand new container is relatively cheap considering the labor outlay is much less.

3. Modularization

Container houses are the Lego bricks of the construction industry. Containers can be combined into a larger structural building, which makes the building simpler, more personalized, and more popular, and it also allows you to participate in the transformation of your own home!

4. Eco-friendly

The average container house weighs about 3500 kg. Used shipping containers not only allow for easy recycling, but also reduce the need for bricks and cement. more to the environment

5. Can container houses withstand hurricanes?

Partially true: After a hurricane or other natural disaster, the container may be blown away by the wind but keep the box intact. If the containers are properly anchored to the foundation, they can withstand high winds.

6. Can container houses be built in my locality? Research building codes in your area!

Different cities (and possibly even different areas within a city) may have different rules and regulations for building container homes. So before starting to build a house, make sure to consult with relevant authorities such as the local planning bureau and understand the relevant issues of approval. Or directly contact the container house production and processing manufacturer, the manufacturer will answer and guide you to solve related problems!

7. Find a suitable container house manufacturer

Housing has been around for thousands of years, but container homes have not. Finding the right fabricator, especially if they have experience with the kind of house you envisage designing, can save detours, reduce construction time, ensure a smooth construction process, and solve many possible problems. You may also want to deal with the project manager for the project and see how it goes, rather than staring at every different internal and external job, but to save money, if you are an insider or if you choose to feel confident, you can manage it yourself The entire project and let the contractor only be responsible for various sub-tasks, such as welding, piping, thermal insulation, etc. Although doing so can save a lot of cost, the final construction effect can only be taken care of by oneself.

8. How to choose the right insulation material?

How to choose the insulation material of the container house? The most convenient option is rock wool board. That’s because it not only insulates, but creates a vapor barrier to keep moisture from entering your container home, and it’s less expensive.

9. Which is the best choice for flooring in container houses?

Carpet or tile? How about durability? A carpet, you can replace it every few years, tiles can be used for a long time and easy to clean, it depends on the individual test!

10. The water supply and drainage pipes of the boxed house are also a very important design

The look and feel of the entire container house can be changed by changing the paint, decoration and decoration, but the plumbing may only be done once. Learn about all the options available and their pros and cons in the long run!

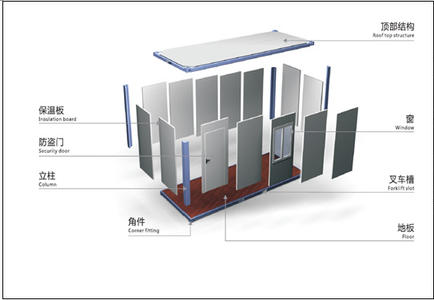

11. Understand the structure of basic containers

When building or renovating a container house by yourself, you don’t need to know the physical and mechanical principles of the container house, but you still need to understand the basic physical structural integrity knowledge. For example, the two long walls are both load-bearing and Supported, so if you’re going to cut a hole in a container side panel and then cut another hole, you’ll need to balance this wall load.

12. Purchase all container materials uniformly from the same manufacturer

Shipping containers from different manufacturers may vary slightly in quality and size, and combining them may eliminate the convenience of using shipping containers to build modular structures. Therefore, it is very necessary to find a manufacturer suitable for your region and needs, and to purchase uniformly.

13. Building your own container house requires a simplified plan

The complexity of building a shipping container home is up to you. Like any type of construction technique, container homes offer a wide range of possibilities. If you don’t have a lot of experience or confidence, you can start simple and maybe try a more complex container building later on. The great thing about container homes is that they’re easy to upgrade, so once you’ve gained your initial experience, you can always add extra rooms, floors, and even a swimming pool!

14. Take the design drawing style you like or design yourself, and go to an experienced manufacturer to discuss or make it.

Every design or “modification” requires the affirmation of professionals. After all, every cutting or welding requires a certain cost. If it is cut wrong, it will take a lot of cost and time to rebuild it, so I want to avoid it. If you are doing invalid work, you should refer to the opinions of professionals.

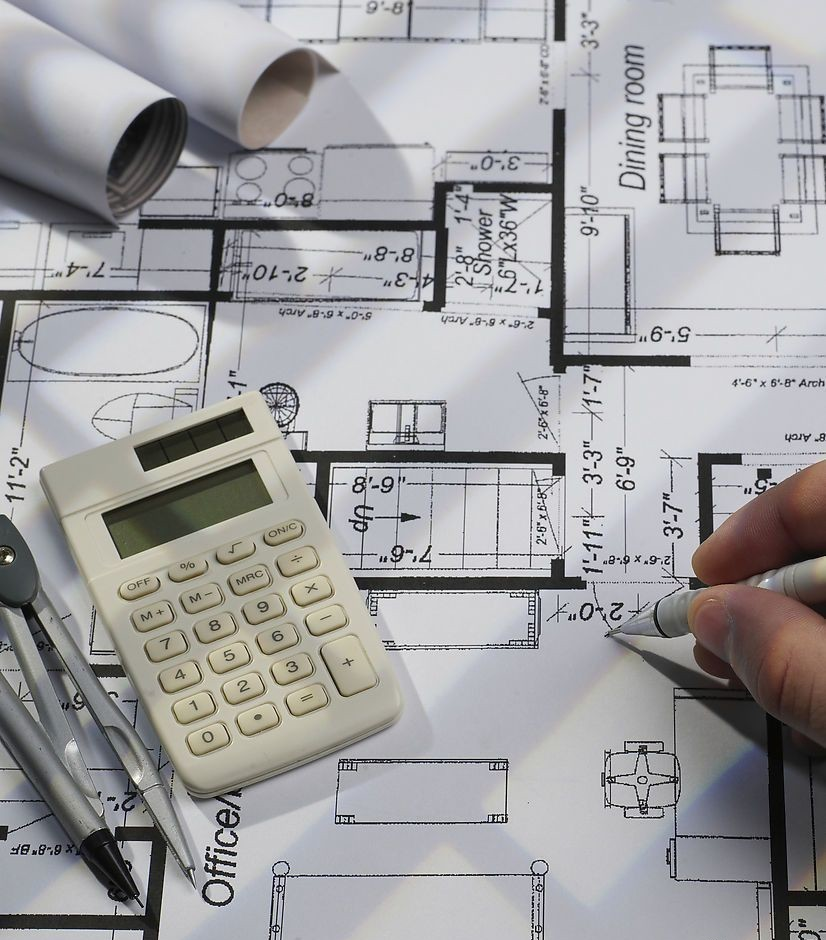

15. Do cost planning and budgeting

If you want to build a container house on a tight budget, you need to have a clear accounting list for the construction/renovation process and various expenses, and calculate the input costs of the container house renovation and various architectural elements , to make sure you don’t end up over budget.

Sixteen, choose a new or second-hand container…

We know that the cost and service life of the house are directly related to the choice of new and old containers. Buying recycled used shipping containers can be cheap, but it comes with its own set of challenges. You’ll also want to carefully inspect any shipping containers you buy, and be prepared for flaws that may become apparent over time. A good compromise is a “disposable” container, which is used only once. They’re cheaper than brand new, but wear far less than retired shipping containers. When you choose the right supplier, you can consult the other party to make the right choice.

Ten, the placement of the corner columns of the container house.

Containers are designed to be stacked on ocean shipping vessels. On board they stacked containers of comparable size one on top of the other, rowing corner post to corner post. If you look closely, you will see that the corner posts are only a little lower than the bottom of the container and a little higher than the top of the container. The corner posts and floor of the container are designed to bear the weight of the container and the container above it. So you want to do the same with your stacking container design. If you are stacking 2×20′ containers and 1×40′ container, make sure the 20′ container is on the bottom so that all four corner posts of the 40′ container have corner posts to set. If done in reverse, the 20′ corner post will not have proper support and the 20′ corner post could fall from the top of the 40′. If your design doesn’t allow this, then just build in brackets for the corner posts.

18. Understanding how stacking enhances structure

The design of the container house is very strong, but only in certain aspects. When they are stacked, their weight is transferred through the corner posts, resulting in high stability. Conversely, this does not apply if the container is to be buried in an underground bunker, which exerts forces (soil weight) on the container roof and walls.

19. Are container houses good? Or prefabricated houses and light steel villas? How should I choose?

In many areas, containers may be available in large quantities and at low prices because it is too expensive to ship them back to the port of origin. In some places, the cost of prefabricated houses may be cheaper, and with the increasingly popular 3D printing material technology, new house construction technologies and materials will be more and more applied to house construction. A new architectural form may be born in the future, but no matter which form you choose, such as container house, prefabricated house, light steel villa or other architectural models, the prices are different, so don’t blindly go horizontally with the cost per square meter For comparison, please choose carefully according to the actual needs (design style, manufacturing cost, logistics and transportation, installation team, after-sales service, etc.), compare prices vertically, and make a rational decision!

Post time: Dec-05-2022